Product center

Contact us

Contact us

Product details

Electrolytic plate automatic feeding and outgoing positioning cart

DZMAL-4-type electrolytic plate automatic access slot positioning travel Xiangtan Volkswagen Rectifier Manufacturing Co., Ltd. carefully designed and developed the patented invention of the product, and has completely independent intellectual property rights (invention patent: 201310329842.7). With the industrialization of the development of the mechanization process The speeding up of this product is bound to set off a new technological transformation in the field of electrolytic manganese production!

At present, most of the domestic production of EMM is mostly done manually by hand, and a handful of companies use semi-mechanized operations. However, the workload and labor intensity of workers are very large, and the production environment is harsh. The production efficiency of enterprises is low and the labor cost is high.

In order to change the status quo, after careful data research and thousands of on-site simulation experiments, Dazmal-4 electrolytic plates have been developed and designed by the public. Finally, DZMAL-4 electrolytic plates are automatically positioned in and out of the trough to fill the national and even the world's manganese The blank of automated production in the industry greatly improves the working efficiency of manganese industry and further reduces the production cost of electrolytic manganese, which has great development prospects and market value.

We use the highest quality materials in the manufacturing, through careful and meticulous processing, the company's automated production of electrolytic manganese stripping line, into a truly able to put into mass production equipment, electrolytic manganese manufacturers can bring excellent Economic benefits.

One, use

1. Electrolysis Pole automatic access slot positioning Travel rely on the bridge along the plant track direction of the vertical movement of the car-driven hanger horizontal movement and lifting spreader special lifting work together to work.

This manual refers to the double girder overhead crane, mechanical and electrical automation through the design and manufacture of electrolytic cell plate into the groove and a dedicated cranes for electrolytic manganese, electrolytic antimony and all other Electrolytic tank within the plate (including the cathode or anode plate) into the groove and the groove to use.

Electrolysis electrode plate automatically out of the slot positioning Driving is not suitable for high temperature (& gt; +600 ℃) and low temperature (& lt; -200 ℃) of the place, with a strong corrosive gas (steam) body place, explosion-proof place.

Second, the technical characteristics and the main parameters

The main parameters of the overhead crane are as follows:

(A) from the weight: 5t-250t

(B) the span: 10.5-33.5m

(C) working level of the crane: A5..A6

In the use of this manual should also refer to the mechanical, electrical standards or supplementary instructions

Third, the structure overview

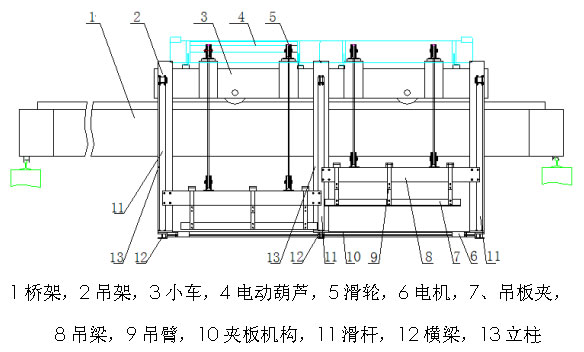

The entire crane is a bridge, trolley, hanger, electric hoist, pulleys, special spreader, splint mechanism and electrical control equipment & nbsp ;.

The crane has two sets of special spreaders (including hanging clamps, lifting beams and jibs). The weight of articles to be lifted should not exceed the rated lifting capacity of the electric hoist. The total lifting weight should be less than the rated lifting capacity of the crane.

(A) metal structure

Metal structures include bridges, carriages and hangers.

1, Bridge consists of: two box-shaped main beam, four box-shaped end beam and the main beam on both sides of the walkway. In the main beam roof laying track (called the rail), for the operation of the car. Walking on both sides of the stage are installed crane operating structure, which took the south side of the stage to install the car hanging cable conduction. Take the outside of the railings are Taiwan. girder and end beam bolted. Two main girder and sub-beam coupling frame by bolting. The whole bridge can be split, easy to transport.

2, a small frame welded steel plate frame structure. The frame is equipped with lifting mechanism and trolley operating mechanism.

3, 6 pillars of the hanger for the square steel, fixed by bolts in the car, the six columns through the upper and lower three beams connected by bolts into 3 groups, each group has a bolt from the middle of the upper and lower beams Slide bar.

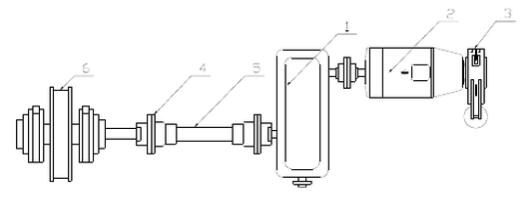

(B) crane operating agencies

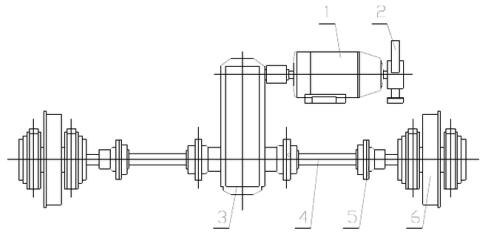

The crane has four wheels mounted on two end beams. Two of them are active wheels and two are passive wheels. The drive device is 1. Reducer, 2. Motor, 3. Brakes, 4. Couplings, 5. Compensation axis, 6. Wheel and other components, the motor is YZP inverter motor, the brake is a hydraulic brake.

(C) hoisting mechanism

Hoisting mechanism consists of 2 electric hoist, 2 electric wire rope hoist pulley connected to a crane beam, crane beam connected to the crane clip.

1, electric hoist electric hoist rated capacity of 3 tons, the use of external components, electric hoist has 2 tow rope.

2, Crane beam: The beam of the crane beam is square steel, the two ends of the crane beam are bolted to each other with two pairs of housings. The bearing ball bearing and the U-shaped roller are installed between the two bearings, so that when the crane beam is lifted U-shaped roller on both ends of the crane beam slide on the slider. To give hanging beam positioning.

3, hanging board folder: hanging board folder is used to lift the plate in the electrolyzer 2 dedicated fixture, hanging plate toothed plate made of bakelite, fixed on the angle, both inside and outside the angle With bakelite wrapped, made of insulation, the top of the boom is the flat bottom of the plastic board. Hoist clamp lifting by the electric hoist control, hanging plate folder opening and closing by the two-cylinder control, cylinder model 50X25

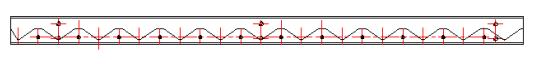

(Four) splint mechanism

Plywood mechanism's role is to use the toothed plate to hold both sides of the plate, when the plate into the cell, the plate will not shake and swing to ensure that the plate into the slot accurately. Plywood mechanism of the two ends of the aluminum beam mounted a total of four bearing seat, the middle of a bearing installed in the aluminum alloy above the level of a plastic board installed from the role of insulation board, glued board mounted horizontally above a toothed plate, toothed plate Stuck the plate at work

The three housings support a long shaft, the ends of the long shaft are equipped with gears, the gears roll on the rack, a sprocket is fixed on the long shaft and connected with the motor, and the motor is fixed on the aluminum alloy beam. The other 2 chocks are equipped with 2 gears and the gears roll on the rack. Positive and negative motor drive gear rack in the reciprocating motion, control toothed plate clamping and release.

(E) car operating agencies

Crane car has four wheels, mounted on the bottom of the car. Two of them are active wheels and two are passive wheels. The drive device has 1. Motor, 2. Brake, 3. Reducer, 4. Compensation shaft, 5. Coupling, 6. Wheel and other components, the motor is YZR motor, the brake is a hydraulic brake.

(F) other equipment

1. Bumper; Both ends of the crane end beam, equipped with cart polyurethane buffer. Car trolley at the end of the car equipped with polyurethane buffer. It is used to reduce the impact of collision with two cranes in the span or cranes and carriage to the extreme positions of both ends.

Note:

1, at work, both the clamp and the clamp mechanism are in live working. Therefore, it is necessary to ensure the insulation of the clamp and the clamp mechanism to prevent metal conductive objects from leaking to the metal parts on the clamp and clamp mechanism Pay attention to the danger of electric leakage.

2, the size of the wheels and reel bearings in the bearing, the hook pulley, fixed pulley and other parts of the rolling bearing can be used on the 3rd calcium-based grease, gear coupling grease, oil mixture heated after lubrication, the ratio For

3, wire rope: In order to prevent the release of steel wire rope and reduce its strength, hoisting mechanism work, should avoid spreader group spinning.

Rope must be properly lubricated on time. Lubricate the old oil with a kerosene-impregnated cloth before lubrication. It is absolutely forbidden to use metal brushes or other sharp appliances to clean the steel wire. It is also absolutely forbidden to use acidic or other highly corrosive lubricants.

As the rope is used for a long time, a portion of the wire in the rope will be worn or broken. Whether or not the wire rope can continue to be safely used is determined by the number of breakage of the wire rope at each pitch of the wire rope. The so-called rope pitch pitch refers to the number of turns on the wire spiral is equal to the length of the number of steel strands. That is, 6 strands of steel wire rope per winding has 18 pitch. Wire rope scrap requirements are based on the place of use, work level and design safety factor to determine. & nbsp ;.

4 gear coupling: The main check its lubrication, sealing and axial displacement of any loose phenomenon, not less than once each year on the coupling gear wear degree of inspection. In case of the following situation should be replaced.

(1) there is a fatigue crack on the root.

(2) gear teeth cracking.

(3) Operating mechanism coupling, when the gear tooth thickness of the wear and tear of the original tooth thickness of 20%. Climbing mechanism coupling gear tooth thickness of the wear and tear up to 15% of the original thickness (when lifting dangerous goods 10%).

5. Reducer: reducer should be regularly checked gear lubrication, gear toothing and bearing temperature and other conditions, such as abnormal circumstances should be immediately shut down for maintenance.

M4P series gear reducer gear with oil splash lubrication, F series gear reducer gear oil bath lubrication. The amount of oil injected into the box measured with a needle, the oil level should reach between the two needle marks up and down. Lubricating oil model see Table 2

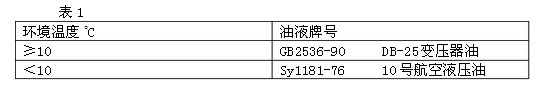

6, brake and other operating system available pin 20 # oil. Pusher oil grades see Table 1

Each gear unit has an oil level indicator, which is a graduated glass or dipstick with the level of oil to be reached by the marker above. When the gear unit is stopped and the hose is full, press the oil level indicator Full of oil is very important. The amount of oil given on the signboard only serves as a guide.

NOTE: It is often not possible to correctly determine the amount of fuel while the gear unit is operating.

(1) For the first gear change 500 to 800 hours after the first gearbox is used, change the oil for the next three years.

(2) The gearbox should be opened every six months to check the lid once, check the gear teeth without pitting, scratches, gluing and cracking and other defects; bearing and seal parts are worn, and according to different requirements for replacement or repair.

(3) The retarder has been made static seal at the factory. When it is out of the box, the residual sealant on the bonding surface should be removed and cleaned. Apply a new liquid sealant (using polymer liquid sealant 601) Glue a little after the polymerization, in the box and tighten the bolts.

(4) Sharp reversing operation greatly reduces the service life of the reducer and affects its safe use, and the above situation should be avoided.

(5) It is only allowed to lift the entire gear unit with lifting lugs on the box body.

(6) bearing and axial clearance adjustment;

A. The gear type used for the deep groove ball bearings or tapered roller bearings.

B. When the bearing is inserted into the shaft, the end face of the bearing inner race should be close to the shoulder or the distance ring, and the clearance shall not pass through the 0.05mm feeler.

C. When using deep groove ball bearings, in order to avoid the deformation of the shaft and its parts when the temperature changes, one of the two bearings on the shaft and the end face must keep 0.4mm axial clearance of 0.2, its size can be adjusted Shims to be adjusted.

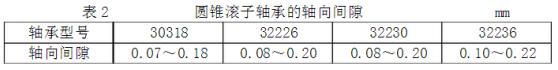

D. The use of tapered roller bearings, the gap can be adjusted by turning the adjusting screw, the gap in line with the provisions of Table 2. (Reference)

When adjusting the axial clearance of the tapered roller bearing, tighten the adjusting screw first and then exit the cylinder 1 ~ 2 with the locking piece to fix the adjusting screw to the end cap. When turning the adjusting screw, turn the shaft at the same time so that the roller is correctly on the raceway.

7. Wheel assembly should be regularly inspected, when one of the following conditions should be scrapped:

(1) Crack.

(2) flange thickness wear up to 50% of the original thickness.

(3) Bending thickness of the flange thickness up to 20% of the original thickness.

(4) Tread wear up to 15% of the original thickness.

(5) When the operating speed is lower than 50m / min, the ovality is 1mm. When the operating speed is higher than 50m / min, the ovality is 0.5mm.

(6) The deviation of two active jobs from uneven wear shall not exceed 1/600 of their nominal diameter. If more than this value should be re-processed, after re-processing of the wheels should meet the provisions of Article 4.

8. The brake wheel should be scrapped when one of the following conditions occurs:

(1) Crack.

(2) Lifting mechanism wheel flange thickness wear up to 40% of the original thickness, the operating mechanism of 50%.

(3) when the unevenness of the tread surface reaches 1.5mm, if it can be repaired and repaired, Article 2 shall be satisfied.

9. The electric hoist reel wire rope at the end of the fixed situation, should be checked once a month, the reel appears in one of the following conditions should be scrapped:

(1) Crack.

(2) Tube wall wear up to 20% of thickness.

Brake:

(1) use and maintenance.

A. The lifting mechanism of hydraulic brakes and electromagnetic brakes should be checked in each shift, run the brakes of the agency at least 2 to 3 days to check once.

B. Pusher for oil leakage and oil leakage. Whether the oil is adequate, the lack of adequate oil should be added, the oil should be replaced regularly, the oil should be cleaned when the machine.

C. Motor lead-in insulation is good.

D. Brake inspection should pay attention to:

(A) Each part of the brake system should have accurate movements. The nuts, safety washers and the like should not be loosened, and the shaft bolts can not get stuck. Check all welds once a month without cracks.

(B) Brake springs, brake arms, brake pads, brake levers, screws, etc., should be replaced promptly if cracks occur.

(C) The plastic deformation of the brake spring should be replaced.

10, the maintenance of metal structures and maintenance. 1. Bridge:

The bridge is the most important force component in the crane's metal structure. The maintenance work is directly related to the safety and performance of the heavy machine. Therefore, be careful when using:

(1) Abrupt start-up, braking, and collision with another cradle must be avoided because of this drastic motion, which results in a significant additional dynamic load on the bridge.

(2) Perform regular deflection measurements on the main girder to verify that the specified deformation is exceeded.

(3) Check the main beam, end beam and main beam connection weld, these are the main weld. If it is found that the weld cracks, immediately stop using. Then cracked weld eroded with high quality welding rod (T42-2) welding should pay attention to the process, to ensure the quality of welding and prevent welding deformation.

(4) When the main girder is found to have residual deformation (or web instability), it should be discontinued immediately. After research, develop a method of repair.

(5) After the bridge is repaired or reinforced, it shall be tested. Refer to the fifth section for the test method. Only after it is qualified can it be applied.

(6) Crane used in open air or under steam shall be supplied with not less than annual paint maintenance to prevent rusting of the metal structure. Indoor cranes should also be painted every 3 to 4 years according to the actual situation. 2. Track:

The main observation track is straight, whether the plate is strong, whether loose phenomenon. If you find the car walking card track, you should try to correct the track or adjust the wheel.

(G) Safety Precautions

1. The crane operator must comply with the relevant requirements of the crane safety regulations.

2 non-overload use.

3. No lifting of the goods crossed in the human head.

4. It is forbidden to use the spreader to lift and lift the heavy objects, it is forbidden to use the crane to pull the buried objects in the ground.

5. It is forbidden to use the limit switch as the stop under normal operation. The limit switch is only the guarantee measure when the operation is inadvertently operated.

6. The crane must give a warning signal before each operation.

7. When lifting heavy objects close to the rated load, you should test whether the brake can be stopped to ensure safety.

News center

Copyright ©2017 Xiangtan public Rectifier Manufacturing Co,.Ltd Powered by www.300.cn Changsha | Mangager | 湘ICP备17009114号-1