Product center

Contact us

Contact us

Product details

Electrolytic manganese automatic stripping line

I, an overview

DZMAL-4 type electrolytic manganese stripping production line is an invention patented product developed by Xiangtan Volkswagen Rectifier Manufacturing Co., Ltd. and has completely independent intellectual property rights (invention patent: 201210168585.9, utility model patent: 201220243352.6). With the development of industrialization , The acceleration of mechanization, this product will set off a new technological transformation in the field of electrolytic manganese production!

At present, most of the domestic production of EMM is mostly done manually by hand, and a handful of companies use semi-mechanized operations. However, the workload and labor intensity of workers are very large, and the production environment is harsh. The production efficiency of enterprises is low and the labor cost is high.

In order to change the status quo, after extensive research and design, Volkswagen has finally developed this DZMAL-4 Electrolytic Manganese Automatic Peeling Production Line through repeated data calculations and thousands of on-site simulation experiments to fill up automation in the manganese industry across the country and even in the world Production of blank, greatly improving the production efficiency of manganese industry, further reducing the cost of electrolytic manganese production, with great development prospects and market value.

We use the highest quality materials in the manufacturing, through careful and meticulous processing, the company's automated production of electrolytic manganese stripping line, into a truly able to put into mass production equipment, electrolytic manganese manufacturers can bring excellent Economic benefits.

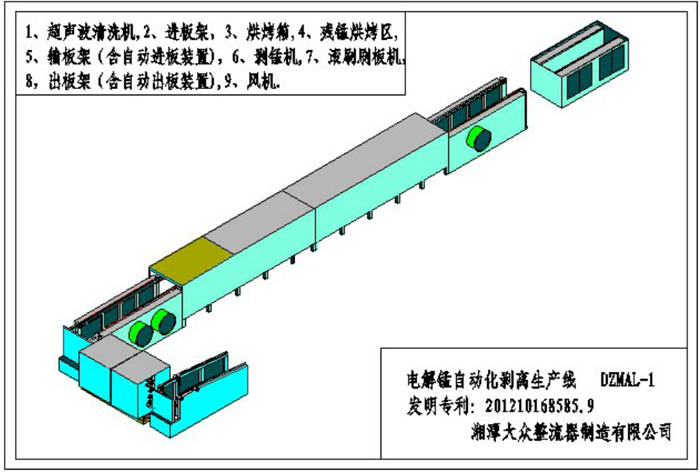

II, construct

The entire process of each production line includes ultrasonic cleaning, plate drying, baking, cooling, into the board, stripping, push plate and other multi-channel production processes, the entire post-processing technology to achieve a mechanized integration of a production line only 3-4 Operators can automatically complete the production process.

II, the working principle:

1. The entire equipment operation includes the steps of product drying, stripping and washing. All equipment adopts automatic control to achieve intelligent automation, rapidity, energy conservation and environmental protection.

Electrolytic Manganese stripping production line peeling off the cathode plate and the processing speed is generally 1500 / hour or so, the work process is stable and safe, easy to operate.

3. Electrolytic manganese stripping production line structure and configuration, according to the order of the process:

1), computer-controlled ultrasonic cleaning machine: DZCSB-1 ultrasonic cleaning machine with independent intellectual property rights of our company is selected for decontamination of cathode plate;

2), into the board rack: will be attached to the cathode with a manganese board hanging into the board device on the chain, driven by the chain;

3), air-drying device: attached to the cathode side of the manganese-air drying device to blow moisture, drying the product cooling;

4) Oven: The heating tube group in the oven will slowly heat the attached manganese cathode to over 100 ℃, rapidly evaporating all the moisture to make the manganese on the cathode dry and brittle. In addition to leave a 2-meter-long box does not install insulation for residual manganese treatment;

5), lose the plate device: Come out from the oven with the manganese cathode plate in the movement by the cold blower to cool to room temperature; the tail plate sub-plate by the conveyor device will be automatically divided by the cathode plate 25 / min; br /> 6), automatic plate feeding device: the sub-plate separated by the manganese cathode attached to the plate by 25 / min automatically into the stripping machine;

7), stripping machine: stripping machine using our company has independent intellectual property rights DZYZ-4 improved electrolytic manganese cathode stripper;

8), automatic out of the device: Manganese from manganese stripping machine out of the cathode plate by the automatic board device pushed to the plate rack gathered.

9), a full set of equipment, electrical installations using PLC-integrated touch screen control, with start down, monitoring, alarm, operation protection and other functions.

IV, the whole features

1. Liberate the workforce, improve business productivity

Fully automatic transmission, the whole process only 3-4 people to complete the operation, with 10,000 tons of production capacity compared to manual or semi-automatic can reduce the workforce at 80% -90%.

2. Save water and reduce environmental pollution

During the cleaning process, the water can be reused, reducing the polluting carrier and easy to handle centrally.

3. Save the cost of the cathode plate

Abandon the original production process, not only can improve the service life of the cathode plate, but also do not need to purchase too much cathode plate to prepare the board, reduce the loss and construction costs.

4. Production processes compact footprint on the ground

6 production processes compact connection, occupy small production area.

5. Smooth transmission of low noise

Transmission parts cycloid reducer with chain drive, so that the transmission is stable and reliable, easy maintenance.

6. Use reliable, long life

Because the main main components are made of high-quality stainless steel, the mechanical properties are good and the chain drive is used again, so it has a long service life.

V, technical parameters:

1. The overall appearance of the size: 17000x3800x1800 (length x width x height);

2. For the board size: 660 * 500 * 1.8, hanging length of 830;

3.Work efficiency: 1 hour per hour can be completed after the work of the cathode plate, a set of equipment for a 5000-7500 tons / year production workshop to provide effective production protection.

4. The total equipment of the largest total load of 126kw / hour, of which the average heating capacity of the oven heat pipe 94kw, the maximum power consumption of the oven fan 4x1.5kw; stripping unit power consumption 2x3kw, the main motor power consumption 2.2kw, 3 cooling fan motor power 3x1.5 kw, washing machine power consumption 12kw, other control and auxiliary device power consumption 2kw.

5. Peel the broken manganese powder within 10%

6. Layout Description: According to the requirements of the workshop site layout, the tail placed in the packing funnel above.

VI, operation and maintenance & nbsp; & nbsp; & nbsp;

(A) operation sequence:

1. Turn on the power & nbsp;

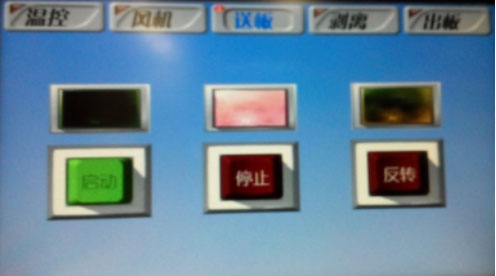

2. Followed by pressing the "electric wire 1, 2, 3, 4, 5, 6 start" button, the electric section opened, preheated for about ten minutes (Figure 1)

Figure 1

3. Press the "Cycle Wind Start" button (Figure 2)

Figure 2

4. Put the manganese plate into the transmission chain of the plate

5. Press the "Start button" button, manganese plate will be sent to the oven (Figure 3)

Figure 3

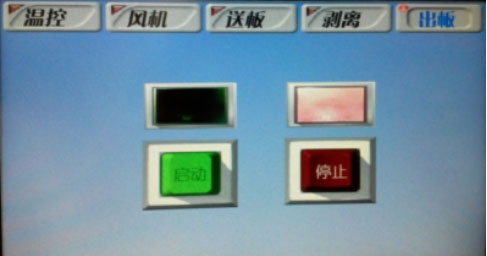

6. Manganese board out of the oven, press the "air-dried cold start" button (Figure 2)

7. When the device at the end of the skateboard device has two manganese plate open "peel start", when the device at the end of the skateboard device manganese plate set full (10 manganese plate around) should immediately stop the plate drive, Press the "board to start" & rdquo; left two manganese plate and then open into the plate drive, so the cycle operation (Figure 4)

Figure 4

8. Press the "Launchpad" button to open the tablet device (Figure 5)

Figure 5

9. Need to shut down operation, when the production line of manganese plate to complete a process can be followed by the closure of a process to complete the entire production process can be completely shut down the entire production line of the total power.

(B) Safety Precautions

1. If the equipment malfunctions or makes an abnormal sound, please shut down immediately. Ask the technician for on-the-spot maintenance. Do not allow non-professionals to carry out maintenance.

2. During operation, it is forbidden to extend body parts or tools into the machine to prevent accidents.

(C) maintenance

1. Lubrication method:

The reducer lubrication method table:

|

lubricating oil |

||

|

Ambient temperature ℃ |

Extreme pressure gear oil |

ISO extreme pressure gear oil |

|

-5~10 |

L-CKC68 |

EP68 |

|

0~35 |

L-CKC100 |

EP150 |

|

30~50 |

L-CKC200 |

EP220-46 |

NOTE: 2 # Lithium Grease, 2 # Extreme Pressure Lithium Grease, or 00 # Reducer is recommended when using a grease reducer for lubrication fat.

1. The reducer must be injected into the lubricating oil before use, the factory reducer in order to facilitate handling and transportation, are generally not installed lubricating oil.

2. When filling the oil, the height of the oil level should not exceed the upper limit of the glass hole oil standard, nor lower than the lower limit of the oil standard. In operation, should always observe the level of oil, replenish the same grade of lubricating oil.

3. Lube oil replacement system:

The first replacement, the reducer 300 hours after the first operation for the first replacement, replacement, should remove the residual oil. After each replacement, continuous work for more than 10 hours per day, once every 3 months replacement; intermittent work for less than 10 hours a day, once every 6 months.

4. Grease replacement system: every 6 months to replace.

5. The gearbox that has not been used for a long time must be replaced with grease or grease before it is restarted.

6. It is not allowed to inject unclean or corrosive lubricating oil.

VII, often using environmental conditions

|

1 |

Altitude |

≤5000m |

|

2 |

Ambient temperature |

-40℃∽+65℃ |

|

3 |

Relative humidity |

15%∽90% |

|

4 |

Environmental pollution level |

Level IV |

|

5 |

Installation method |

Indoor |

1, electrical conditions:

Line voltage: 380VAC +10% 3PH, 50HZ + 1%. Requirements of power supply conditions to GB / T3859.1-93 5.2 in the general requirements of the industrial power network (ie Class B) requirements, the rectifier in the B Class electrical can operate normally

Frequency: 50 & 1% HZ

Voltage fluctuation range: 5%

2, the device must be mounted vertically, its inclination must not exceed 5 & deg .;.

3, the scene conditions of use do not meet the above, by the user and manufacturer negotiated settlement. strong>

VII, photos

Note: Total 5 Pages, Page 1 Overall Appearance Installation Drawing; Page 2 Main Circuit Diagram; Page 3 PLC Control Circuit; Page 4 Operation Panel Indicator Diagram; Page 5 Motor Protection, Remote Control Box, Main Cabinet Terminal Figure strong>

News center

Copyright ©2017 Xiangtan public Rectifier Manufacturing Co,.Ltd Powered by www.300.cn Changsha | Mangager | 湘ICP备17009114号-1