Product center

Contact us

Contact us

Product details

Electrolytic negative plate manganese peeling machine

I. Overview

DZYZ-4 cathode electrolytic manganese stripping machine is Xiangtan Volkswagen Rectifier Manufacturing Co., Ltd. carefully designed and developed by the utility model patent products, and has completely independent intellectual property rights (invention patent: 200910044145.0, utility model patent: 200920065607.2). With the industrial The development of mechanization, the acceleration of the process of mechanization, the product is bound to set off electrowinning manganese cathode strip in the field of a new technological change!

At present, all domestic electrolytic manganese plate removal work is done by manual manual tapping, and the work efficiency is low. In addition to the heavy workload and labor intensity of the plate, the long-term staff members are in dusty and loud noises Environment, there are potential threats to their health. After many visits that board workers in addition to the board is a very large liquidity position, the flow of personnel in virtually the normal operation of enterprises also have a certain impact, we can see that manual manual operation is no longer adapted to modern businesses The development model.

After our observation in many EMM plants, manual manual knocking work not only poses a threat to health, meanwhile, manual knocking can also cause different degrees of damage to the manganese plate. Some manganese plates suffer from the impact of gravity and the cathode Uneven beat marks will be left on the top of the board, which will greatly reduce its service life and even cause permanent damage. In order to change the status quo, after careful data research and thousands of on-site simulation experiments, Dazy-ynx4 has finally developed the DZYZ-4 metal manganese cathode plate stripping device to fill the national and even the world's manganese industry Stripping manganese products blank. Greatly improving the work efficiency of manganese stripping, further reducing the cost of electrolytic manganese, with great development prospects and market value. In manufacturing we use the highest quality materials, precision fine-crafted, making it a real set can be put into mass production equipment.

II. How it works:

The invented electrolytic cathode stripper manganese stripping machine uses a pressure roller to transport the electrolytic manganese dioxide cathode plate, and the working parts are a number of pairs of relative pressure rollers. The basic principle of operation is as follows: the cathode plate adsorbed with manganese is subjected to positive pressure in the normal direction of the pressure roller and the static frictional force in the tangential direction by the pair of pressure-roller cathode plates intermeshing with each other, Law bending elastic deformation, while the horizontal displacement of the elastic deformation of the surface attached to the cathode plate hard and brittle metal manganese layer rupture and fall off, to peel effect. The horizontal displacement is played a role in transmission, so that from the number of pairs of negative pressure plate between the smooth through. Due to the special misalignment of the pressure roller pair, the deformation of the cathode plate can be resumed, so as to ensure the original shape of the plate.

The main features of this machine are: ① liberate the labor force, improve labor productivity. ② each pair of pressure roller meshing gap can be adjusted, so as to obtain the ideal stripping effect, while compared with manual methods, to avoid plate damage, extend the service life of the plate. ③ transmission parts cycloid reducer with chain drive, so that the transmission is stable and reliable. ④ working part of the stripping machine fully enclosed working environment, to avoid dust and oil into the manganese, affecting product quality. ⑤ stripping of the metal into a sheet of manganese, manganese crushing rate of less than 10%.

III. Technical parameters:

1, the machine is a practical metal manganese cathode plate size 500 × 600 (according to the demand side set)

2, the machine on the cathode strip peel speed of about 25 per minute board

3, stripped manganese powder crushing rate of less than 10%

IV. Installation procedures and procedures:

1, open the stripping machine roof, check whether the parts of the screws loose, if reinforcement please.

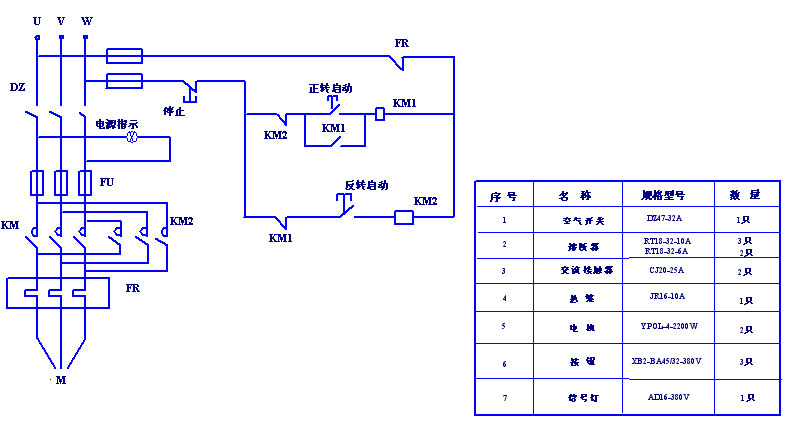

2, connected to 380V power supply, turn on the air switch to see if there is power indicator.

3, close the contactor to see 2 motor (6KW) is functioning properly, whether the reverse, if it is reversed, immediately turn off the power and the three-phase power into the line of any two of the opposite, you can re-connect It's If the motor is not running, the fuse may be blown, please replace the 16A fuse (Please note that the fuse must be 16A, or the current is too small, easy to burn the fuse, the current is too large, easy to burn out Motor).

4, empty machine running for a period of time to see if there is abnormal noise, if any, please stop checking immediately, shall not overhaul in operation.

5, the metal cathode plate should be parallel to the bottom of the import roller skateboard, from the import into the stripping machine, pay attention to this process can not be tilted, otherwise it may cause pallets phenomenon.

6, the whole machine in operation, please put a manganese cathode plate into the stripping machine imports, to be stripped out from the exit, please check the stripping effect is good, manganese flakes are all spalling, such as peeling is not satisfactory, can The pressure roller up and down at the same time tighten each other about 2mm, until the desired effect of peeling so far.

7, in the process of delivery plate, must wait for a cathode plate out from the outlet, in order to carry out the next operation of the cathode plate.

8, Into the board, it is prohibited to hand or foot into the machine, the operation may not be hand or tool and other objects into the machine push plate to prevent accidents.

9, in case of pallets, press the reverse start button, so slowly exit.

10, the cathode plate from the oven, it must be cooled to below 45 ℃ before entering the cathode plate stripping operation, otherwise it will cause damage to the nanometer material roller, such as the cathode plate temperature exceeds 45 ℃ caused damage, then not Belongs to my company within the scope of warranty.

11, each shift before boot, please shift personnel on a full inspection of the stripping machine:

● Check all parts of the screws are loose, if you have to reinforce

● If you need to adjust the gear, you must ensure that the gear is perpendicular to the shaft and should not be inclined ● Please test the import roller skate level

V. Often use the environmental conditions required: (see the table below)

|

1 |

Altitude |

≤2000m |

|

2 |

Ambient temperature |

-15℃∽+45℃ |

|

3 |

Relative humidity |

15%∽90% |

|

4 |

Environmental pollution level |

Level IV |

|

5 |

Installation method |

Indoor |

1, Electrical conditions:

Line voltage: 380VAC +10% 3PH, 50HZ + 1%. Requirements of power supply conditions to GB / T3859.1-93 5.2 in the general requirements of the industrial power network (ie Class B) requirements, the rectifier in the B Class electrical can operate normally

Frequency: 50 & 1% HZ

Voltage fluctuation range: 5%

2, the device must be mounted vertically, its inclination must not exceed 5 & deg .;.

3, the scene conditions of use do not meet the above, by the user and manufacturer negotiated settlement.

News center

Copyright ©2017 Xiangtan public Rectifier Manufacturing Co,.Ltd Powered by www.300.cn Changsha | Mangager | 湘ICP备17009114号-1